Managing the Complexity of Updates for Multiple Automotive Systems

March 25, 2020

Story

More than most other in-car technologies, products within these domains cover a broad spectrum of technologies and performance levels.

Comfort, body, and lighting substantially influence consumer satisfaction, but there are intense competitive cost pressures in play. More than most other in-car technologies, products within these domains cover a broad spectrum of technologies and performance levels. For example, actuators with small microcontrollers, minimal memory, and no OS on a LIN bus, might be mixed with devices using RISC processors, running AUTOSAR on a CAN bus.

None of these devices will typically be over-provisioned. They will have the resources needed for the function they provide, while cost competitiveness will not allow for extra un-used resource.

To take advantage of the benefits of over-the-air (OTA) updating technology, and to keep all in-car devices up to date, there’s a need to handle the complexity of all these different standards and technologies. Different ECUs have different processing resources and different amounts of memory. Security requirements, delta reconstruction techniques, roll-back mechanisms…all of these OTA related functions can impact the processing and memory needs of an ECU. Without a standard approach, any Tier-1 would only be guessing if they put extra resource into a device for OTA related functions. And this is not an industry that rewards guessing.

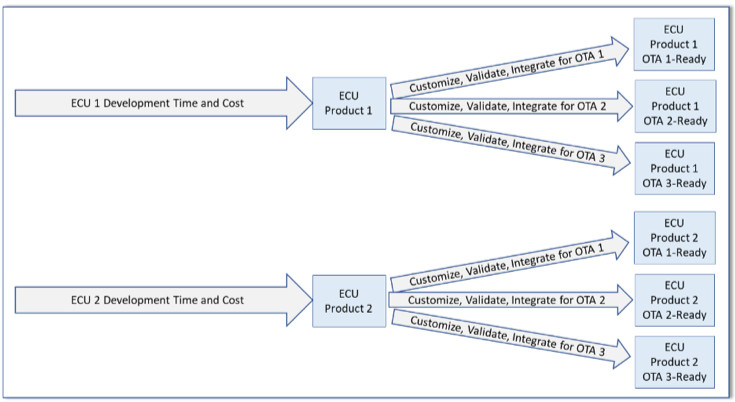

With this proliferation of different approaches, suppliers face unfamiliar OTA technology for each OEM project. With proprietary approaches, ECUs need custom engineering to provide extra resources. The resources are coupled with increased testing costs to validate the ECU functions within an OTA data pipeline. Proprietary pipelines mature slower than standard, widely adopted pipelines. On the industry’s current path, ECU providers who do business with multiple OEMs will need to implement multiple OTA techniques, requiring slow, costly custom development. Every OTA platform will add cost to every ECU. So, every OTA platform will add cost and time to the development of every car.

Fig. 1: In a proprietary OTA environment, there is a separate engineering task for integrating each ECU into each OTA solution, including within Tier-1s with multiple teams.

A standard pipeline will mature faster. Within any Tier-1 supplier, their experience in the standard will be shared across multiple vehicle projects, so that new projects can intercept the learning curve at higher levels. Across the industry a wider range of users will implement a broader set of use-cases. In this environment any weaknesses in the standard will be more quickly recognized and addressed than in proprietary approaches. Standardization of the pipeline will encourage development tools, validation tools and test suites.

On the OEM side, costs are reduced by providing a mechanism for Tier-1s to pre-provision their devices for OTA. They can be validated for OTA performance and reliability against standard platforms, reducing the costs and time for testing during vehicle integration. Widespread adoption of an OTA pipeline to all the devices in the car will encourage innovation by focusing teams on developing new features related to connected car potential, instead of integrating and validating multiple OTA mechanisms.

As we trend towards a higher individualization of the vehicle, OTA provides valuable opportunities for customization and personalization. Widespread adoption of a standard OTA pipeline will encourage innovation by focusing teams on developing new features rather than integrating and validating multiple OTA mechanisms.

There may be any number of value-added features-on-demand offered for a customer OTA installation, ranging from custom lighting to advanced human-machine interfaces. As well as giving carmakers a competitive edge due to greater differentiation, this can also provide a valuable revenue stream after a car has been sold. For example, an upgrade to the vehicle’s headlights could be offered as a chargeable, software-only OTA update, which unlocks new features once installed.

With so many programmable devices in the car, there is a risk that Tier 1s and automakers may be overwhelmed by the complexity of multiple proprietary OTA approaches. Instead, we need to move towards a common data pipeline that can be built from the cloud to each end device in the car. This is the objective of the eSync Alliance, an open trade association creating OTA solutions specifically designed for the automotive industry.

__________________________________________________________________________________________________________

OTA Considerations: A blog post series by members of the eSync Alliance, an open industry consortium dedicated to automotive OTA software standards. www.eSyncAlliance.org

- https://www.embedded-computing.com/home-page/ota-updates-requirements-for-the-server-in-the-cloud

- https://www.embedded-computing.com/home-page/in-vehicle-networking-requirements-for-ota-updates

- https://www.embedded-computing.com/home-page/how-automotive-infotainment-can-benefit-from-ota-updates

- https://www.embedded-computing.com/home-page/keeping-cars-safe-with-ota-updates

- https://www.embedded-computing.com/home-page/managing-the-complexity-of-updates-for-multiple-automotive-systems

- https://www.embedded-computing.com/home-page/keeping-connected-cars-safe-and-secure

About the eSync™ Alliance

The eSync™ Alliance is an industry initiative to drive a multi-company solution for over-the-air (OTA) updates and diagnostics data in the automotive electronics space, potentially saving billions of dollars per year for automakers. By working together in the Alliance, companies will benefit from a simplified development environment made possible by a standardized yet customizable open platform. The Alliance released version 1.0 of the eSync specification in April 2019. A synopsis is available at https://www.esyncalliance.org/downloads/

Hella GmbH is a member of the eSync Alliance. www.hella.com

eSync is a trademark of the eSync Alliance. More information about the eSync Alliance is available at www.eSyncalliance.org